| BIOMODEL.COM | Quick links: Order a Model | Request a Quote | Send Scan Data |

Advantages of Custom Anatomical Models

MRI and CT scans are currently the diagnostic basis for most complex surgeries. At BMI we use MRI and CT scan data to produce highly accurate, three-dimensional, life-sized medical models.

The use of accurate patient-specific anatomical data in our Biomodels and BioCAD can play critical roles in personalized medicine, the study of various pathological anatomies, and the development of medical devices.

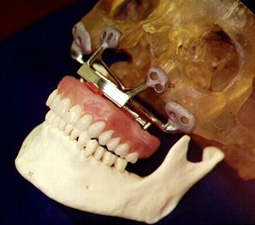

Because human vision is stereographic and surgery is largely tactile, there are significant advantages of examining a three-dimensional model in your hands over viewing a two-dimensional rendering through a screen. BMI biomodels offer the advantages of three-dimensional visualization, a tactile interface, high measurement accuracy and precision and a platform for personalized medicine.

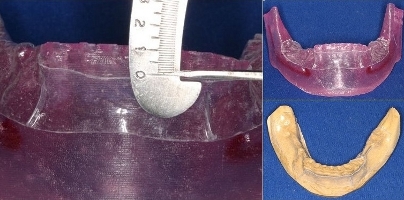

Biomodel used in patient-specific orbital implant production. |

Personalized MedicineThe use of Biomodels has enhanced the design and fabrication of prosthetic implants, improving and simplifying the process. Patient-specific models used as molds or templates allow for the production of personalized-fit implants. Scientists and engineers can utilize Biomodels and BioCAD in the experimentation of subjects under study and the testing of medical devices on specific pathologies. Through anatomical engineering BMI can design and incorporate assembly features into the models, scale, mirror-image, and otherwise manipulate anatomical features as needed.

|

|

Follow the links below to learn more about:

|